Proportioning / Weighting

Raw materials from the quarry are discharged into hoppers. Proportioning is ensured by regulated box feeders then the matters are transferred by band conveyors to weighting stations in order to adjust the various matters.

Regarding powder materials, we supply hoppers equipped with rotary valve feeders and worm screws to ensure distribution and transfer.

Grinding / mixing

Raw materials grinding and mixing can be performed on dry track with hammer or pendular mills – or on wet track with roller mills

The choice of grinding technology is made according to the raw materials used, the required grinding particle size and to the type of products to be manufactured.

Matters are then humidified in shaft mixers then stored in clay stores.

Extrusion

Clay is shaped in an extrusion unit commonly referred to as the extruder.

Equipped with a mixer adjusting water quantity, the extruder is associated to a de-airing unit and equipped with crushing rolls to extrude the clay body under pressure.

At the exit of this unit, a die is installed allowing the fabrication of bricks, roof tiles or any other type of ceramics or heavy clay products.

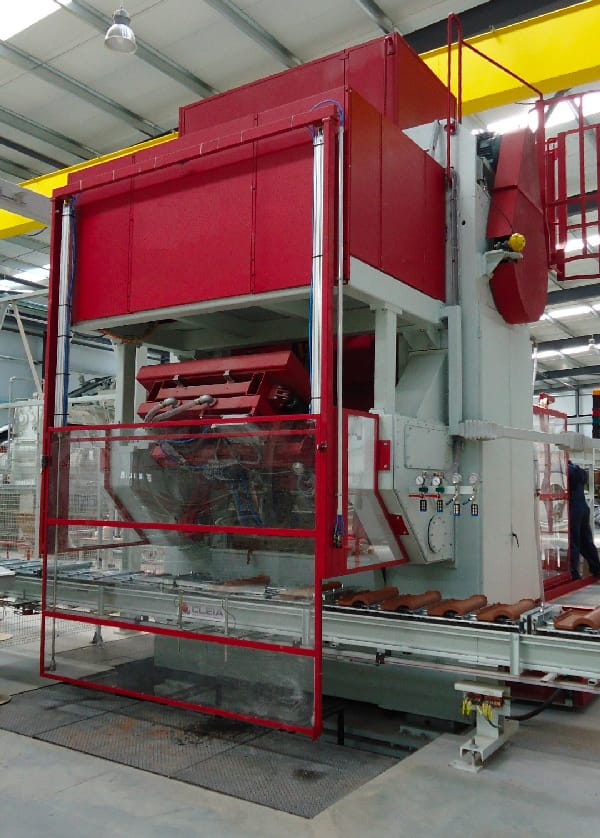

Pressing

Pressing roof tiles allows to obtain their final shape, contributes to the product appearance and also makes it possible to give the characteristics of a roofing tile: overlapping, laying lug...

Barrel hydraulic presses for roof tiles are equipped with a hexagon supporting the lower moulds and with upper moulds adjusted on lamination shaft.

An automatic trimming machine sets pressed tiles on drying trays.

For accessories, turntable presses allow the manufacturing of most standard accessories: ridges, edges…