Heat waste repurposing – France

Heat waste repurposing installation

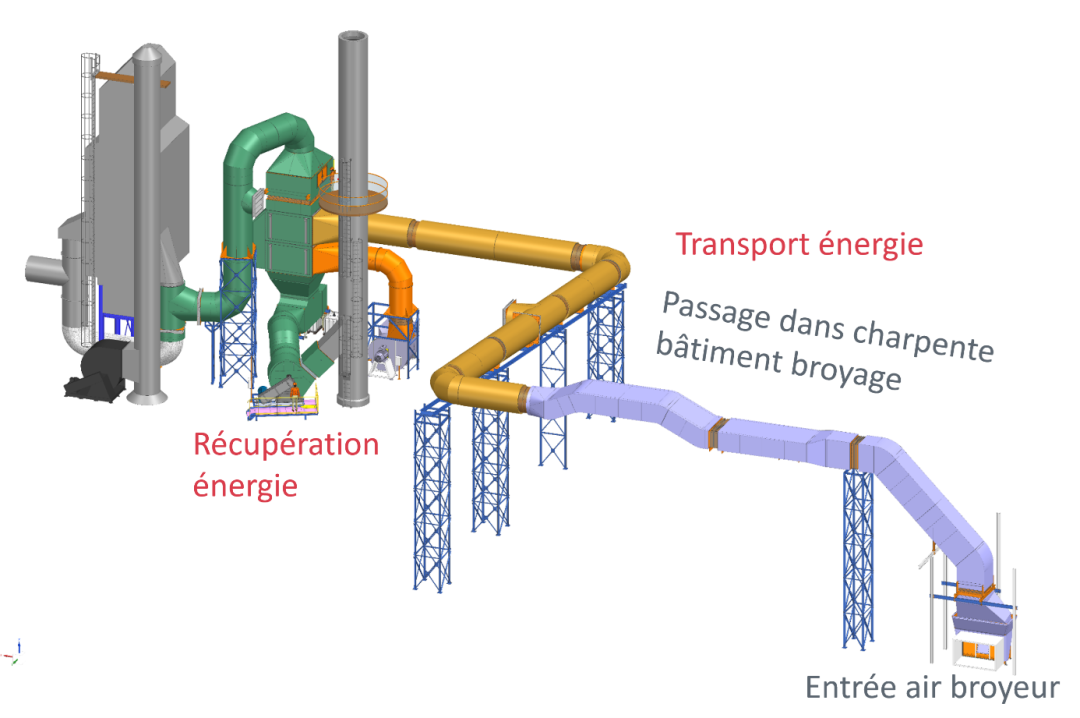

An exchanger composed of 6300 glass tubes, so exchange surface area of 1500m2, was installed prior to the chimney. So, the temperature of the emissions goes from 200°C to 60°C. The heat captured is transferred, then transported in the form of hot air to the material preparation station by the swing-hammer mill.

-50% GAS. The swing-hammer mill which, until now, used 18,000 MWh/year of gas to prepare the ground before its use, saw its consumption be reduced in half.

-10% GREENHOUSE GAS. This project has led to the reduction of 10% of the CO2 emissions on the Chagny 2 site.

The installation was set up in concurrent operation time by adapting to the site’s constraints.

The production switch-over was made in half a day.

The installation management is transparent for both the kiln and the milling installation whose operations are not disturbed.

The optimisation of the aeraulic network has led to the obtention of a coefficient of performance (COP) significantly greater than the one expected.