OUR KNOW-HOW

CLEIA, provider of comprehensive industrial solutions, guarantees the proper functioning and optimal performance of your installations. Our commitment towards innovation and adaptability is reflected in each aspect of our approach. From the design to the creation, not forgetting our service provisions, CLEIA offers you assistance at all stages of the project until the operation stage

DESIGNER & CONSTRUCTOR

FEASIBILITY STUDY

CLEIA is your partner from the beginning of your reflections on a project and can assist you or carry out a technical feasibility and economic viability study for you:

- Searching for raw materials, analysing energy problems, etc.

- Initial market research, financial modelling and business plan construction etc.

Such a study allows for the validation of a project’s hypotheses and establishment of the key choices before the creation stages.

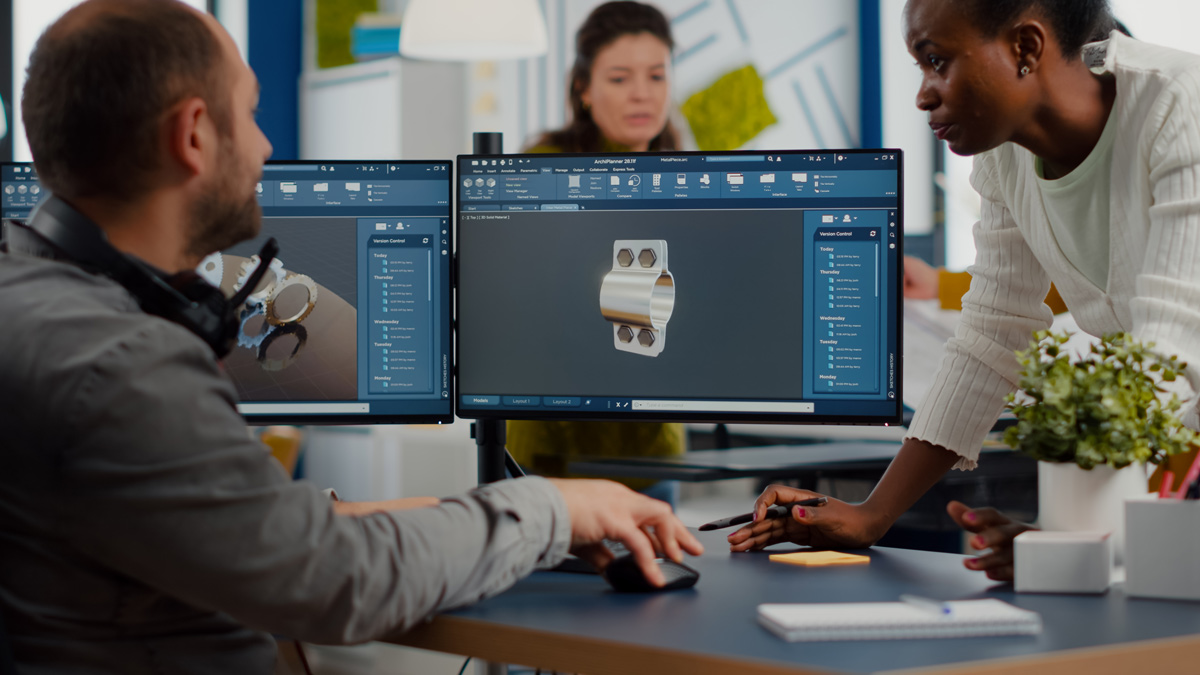

DESIGN AND MODELLING

As a comprehensive engineer, CLEIA can design and model your entire project with you, whether it is an isolated machine, a production cell, an improvement of what exists or a whole industrial site.

LABORATORY TESTS AND ASSISTANCE PROCESS

Thanks to its 4C laboratory (CLEIA ceramic competence centre), CLEIA and its dedicated process team offer you proper assistance in the analysis, definition and characterisation of your raw materials. Firing, drying and milling tests, and other industrial procedures will let you assess the feasibility of your projects as effectively as possible.

DESIGNER, MANUFACTURER AND INTEGRATOR OF EQUIPMENT

From the plans to the machine, we control each manufacturing process and we assemble and test each line before shipping to our clients. The tests in our workshops enable a quicker on-site commissioning. Thanks to our network of specialist manufacturing partners, we can guarantee the quality of all the equipment.

PROJECT MANAGEMENT

CLEIA, as an EPC (Engineering, Procurement, Construction) provider, is able to manage your entire project, regardless of the distribution of the tasks and supplies. Thanks to our dedicated project monitoring service, we ensure the coordination of implementations while guaranteeing development and compliance with schedules and budgets

TRAINING

CLEIA offers training sessions, either at our premises or directly at yours, for plant operation and maintenance staff, whether that is technicians, operators or managers. Thanks to its partners, CLEIA can also assist you in the establishment of communications and training sessions for your clients in order to facilitate the implementation of the products that you offer them.

SERVICES

AUDIT/ADVICE

CLEIA’s specialists and experts are at your service to maintain and improve the performance of your units:

- Audits: thermal and aeraulic assessments, analysis of product flows, machine availability rates etc.

- Inspections and compliance-upgrading: gas, electricity and robotics

- Firing and drying tests, analysis of raw materials in our 4C laboratory

CLEIA will assist you in the transformation of a maintenance operation into an optimisation action:

- Identifying levers for the improvement and development of your production tool

- Reducing the energy consumption of your installations

- Optimising the productivity of your production tool

- Compliance upgrade of safety equipment

TECHNICAL ASSISTANCE

Our priority is fast intervention.

A single point of entry for all your technical assistance needs.

A technical support team who are highly qualified in problem diagnosis and solving methods:

- With remote access solutions, we can quickly identify the cause of most of your equipment’s problems.

- An ability to quickly engage the suitable technical contact person.

- A hotline service for certain sensitive equipment.

SPARE PARTS

CLEIA preserves the functional capacities of your equipment by providing high-quality spare parts.

We provide you with detailed maintenance plans based on methodological processes and our experience in the field.

- Maintenance recommendations constantly supplemented with feedback from our team in the field

- A specific service to help you organise your regular maintenance activities

LINE ORCHESTRATOR

cleiaOS is a leading-edge solution for 360 degree plant management, focused on eco-energy operations. This is a real turning point for the manufacturing sector, offering task orchestration methods to optimise both energy consumption and production speeds. Our system offers a centralised maintenance service which streamlines the operations and improves the reaction times. Designed for maximum flexibility, cleiaOS seamlessly integrates into your IT infrastructure and existing plants. Our no-code interface enables easy customisation, giving you full control over your production chains.

MODERN ARCHITECTURE

The micro-service-based architecture has several advantages, especially for a plant management solution as complex as cleiaOS.

Here are some key points:

ERGONOMICS

User well-being

OPENNESS

Adaptability

FAST DEPLOYMENT

Simplicity

Roadmap

Scalability

Orchestration

Productivity

Maintenance

Cost of operation

IT INTEGRATION (N3)

Interoperability

CYBERSAFETY

Security

ECO-DESIGN

€ / CO2

Support

Reactivity

OPERATIONAL CONDITION MAINTENANCE

Cost of operation

PRICING

No user cost

In summary, cleiaOS’s micro-service architecture offers a robust, flexible and scalable solution which can adapt to the complex and changing needs of modern plant management.

WHY CHOOSE CLEIAOS?

Clients should choose cleiaOS over a competing product for many important reasons:

ADVANCED ENERGY

MANAGEMENT

cleiaOS is designed with an approach focused on energy consumption, allowing plants to function more sustainably and profitably.

NO-CODE

FLEXIBILITY

Thanks to the no-code interface, production managers can easily adapt the processes without requiring programming skills, making the plant more reactive to the changing requirements.

SMART

ORCHESTRATION

The multiple task orchestration methods ensure that production can be optimised in accordance with various criteria, such as the energy, speed or history of the production.

CENTRALISED

MAINTENANCE

The centralised maintenance system based on the LLM accelerates problem solving by providing instructions in natural language, thus increasing the availability of the machines.

REINFORCED

CYBERSAFETY

Compliance with ISO Standard 27001 and the GDPR guarantees a high level of safety and data protection.

PERFECT

INTEGRATION

cleiaOS easily integrates into the existing ERP, MES and WMS systems, thus ensuring a smooth transition and a fast implementation.

MICRO-SERVICES

Architecture: This architecture allows for easy scaling, increased resilience and a simpler integration with other systems.

SCALABILITY

Designed to adapt to new installations and existing plants, making the adoption of cleiaOS easier and faster.

ECO-DESIGN

cleiaOS is developed to minimise its own environmental impact and that of the plant which it manages, which is an undeniable advantage in the context of a sustainable economy.